WARNING: FOLLOW ALL SAFETY INSTRUCTIONS WHEN HANDLING BATTERIES! ALWAYS WEAR SAFETY GLASSES AND A FACE SHIELD WHEN WORKING ON OR NEAR BATTERIES

CORROSIVE

Battery acid, or electrolyte, is a solution of acid and water that can destroy clothing and burn the skin. Use extreme caution when handling electrolyte and keep acid-neutralizing – such as baking soda or household ammonia mixed with water readily available.

FLAMMABLE

Lead-acid batteries can be flammable because they can produce explosive hydrogen and oxygen gases during charging:

- Charging: When a lead-acid battery is charged, electrolysis occurs, which produces hydrogen and oxygen gases. These gases can escape through the battery’s vents. If the gases build up in a small space and come into contact with a spark or flame, they can ignite or explode.

- Electrolyte levels: If the electrolyte levels in a battery are low, it can create space for hydrogen and oxygen to accumulate, which can lead to an explosion.

- Short circuits: A short circuit can cause a lead-acid battery to catch fire.

- Overheating: Overcharging a battery can cause it to overheat and catch fire.

To prevent a lead-acid battery from becoming flammable, you can:

- Keep the battery away from any ignition sources, such as open flames, smoking, or spark-producing tools.

- Charge the battery in a well-ventilated area.

- Follow the manufacturer’s instructions for charging the battery.

EXPLOSIVE

Batteries contain sulfuric acid and produce explosive mixtures of hydrogen and oxygen. Because of self-discharge action generates hydrogen gas even when the battery is not in operation, make sure batteries are stored and worked on in a well-ventilated area. Always wear safety glasses and a face shield when working on or near batteries.

POISONOUS

Lead-acid batteries contain lead and sulfuric acid, both of which can be poisonous:

Lead

A toxic metal that can cause a range of health problems, especially in children. Symptoms include abdominal pain, headaches, memory problems, and tingling in the hands and feet. In severe cases, lead poisoning can cause seizures, coma, or death.

Sulfuric acid

A highly corrosive acid that can cause burns, poisoning, blindness, and internal organ damage. If swallowed, sulfuric acid can cause throat swelling, burns in the mouth and throat, and pain in the mouth and throat. Swallowing sulfuric acid can lead to breathing difficulty, speech problems, and vomiting with blood.

KEEP CHILDREN AWAY

Ensuring that children stay away from lead-acid batteries is crucial for their safety and well-being. These batteries contain hazardous materials such as lead and sulfuric acid, which can cause serious health issues if ingested or if they come into contact with skin and eyes. Lead exposure can lead to neurological damage, developmental delays, and other long-term health problems, while sulfuric acid is highly corrosive and can cause severe burns. Additionally, the heavy weight and sharp edges of lead-acid batteries pose physical injury risks. To protect children, always store batteries in secure, locked areas out of their reach, use child-resistant containers, and educate family members about the dangers associated with these batteries. Proper handling and storage not only prevent accidental ingestion and injuries but also promote a safer environment for children.

FIRST-AID

In the event of an accident involving lead-acid batteries, immediate first aid is crucial to minimize harm. For skin contact with battery acid (sulfuric acid), promptly rinse the affected area with plenty of water for at least 15 minutes and remove any contaminated clothing. If battery acid comes into contact with the eyes, flush them gently with water for at least 15 minutes and seek medical attention immediately to prevent serious damage. In case of ingestion, do not induce vomiting; instead, rinse the mouth thoroughly with water and contact emergency medical services or a poison control center right away. If a battery causes burns or other injuries, apply first aid measures such as cooling the burn with water and covering it with a clean, dry cloth while awaiting professional help. Additionally, if inhalation of battery fumes occurs, move the person to fresh air and seek medical assistance if breathing difficulties arise. Always wear appropriate personal protective equipment, such as gloves and eye protection, when handling lead-acid batteries to prevent accidents. Prompt and proper first aid response can significantly reduce the severity of injuries and improve outcomes in incidents involving lead-acid batteries.

SAFETY – PPE

Wearing safety glasses and personal protective equipment (PPE) is essential when handling or working with lead-acid batteries to ensure safety and prevent injuries. Lead-acid batteries contain hazardous materials such as sulfuric acid and lead, which can cause severe chemical burns, eye damage, and respiratory issues if they come into contact with skin or are accidentally splashed. Safety glasses protect the eyes from acid splashes and debris, while gloves safeguard the hands from corrosive substances. Additionally, wearing protective clothing, such as aprons and long sleeves, and using face shields can provide further protection against spills and splashes. Proper footwear and ventilation are also important to minimize exposure risks. By consistently using the appropriate PPE, individuals can effectively reduce the likelihood of accidents and create a safer working environment when managing lead-acid batteries.

Starting, Lighting and Ignition Batteries (SLI)

Storage and Transportation

- Batteries should be stored in a cool, dry area in an upright position.

- Never stack batteries directly on top of each other, unless they’re in cartons.

- Do not stack more than 3 high, 2 high if the battery type is heavy commercial.

- Test wet (flooded) batteries every 4-6 months and recharge if necessary.

- Batteries should be properly secured during transportation.

- At the latest, recharge starter batteries in the case of open-circuit voltage ≤12.5 V (see Note 3).

- Declaration of all conventional starter batteries wet and filled with acid in accordance with UN 2794. All recombination batteries (AGM, GEL, VRLA) correspond with UN 2800.

Installation and Removal

- Follow the vehicle instructions.

- Switch off the engine and all power consumers prior to installing or removing the battery.

- Avoid short circuits due to tools.

- When removing the battery, first disconnect the negative (-) terminal and then the positive (+) terminal.

- Interruptions to the power supply may result in data loss. The Memory Saver can help.

- Prior to installing the battery, clean the battery compartment.

- Ensure that the battery is secured tightly.

- Clean terminals and battery clips and lubricate slightly with acid-free grease.

- When fitting the battery, first connect the positive (+) terminal and then the negative (-) terminal. Ensure that the clips are secured.

- Some vehicle batteries are fitted with a hose and an elbow attachment for the discharge of the battery gases. Should this be the case in your vehicle, the hose is to be inserted into the corresponding degassing vent in the battery via the elbow. If a degassing vent exists on the other side, this must be closed with a sealing plug.

- Should you require a replacement sealing plug, or a degassing hose, please contact your local automotive specialist.

Charging

- Before recharging wet, non-maintenance-free batteries, inspect the electrolyte level. If needed, add deionized or distilled water until it reaches the maximum acid level mark or is no more than 15 mm above the top of the plates.

- It is recommended that standard wet / flooded batteries be charged outside the vehicle for 24 hours.

- Warning! Many chargers offer a refresh mode specifically for deeply discharged Ca/Ca (calcium) batteries. However, this mode maintains a charging voltage of only 16 V and does so for a limited duration.

- AGM batteries: Always use a voltage-regulated charger with a maximum of 14.8 V for recharging. Using a standard charger without voltage control can damage the battery by causing overcharging and may result in electrolyte leakage.

- Warning! Follow the vehicle manufacturer’s instructions when disconnecting the terminals.

- Batteries must only be charged with direct current (DC). Connect the positive (+) battery terminal to the positive (+) terminal of the charger, and the negative (-) battery terminal to the negative (-) terminal of the charger.

- Ensure the battery is connected before turning on the charger. Once charging is complete, always turn off the charger before disconnecting if from the battery.

- It is recommended that the charging current be at least one tenth of the battery’s capacity. For example, a 50 Ah battery should be charged with a current of 5 A.

- Follow the vehicle instructions.

- Switch off the engine and all power consumers prior to installing or removing the battery.

- Avoid short circuits due to tools.

- When removing the battery, first disconnect the negative (-) terminal and then the positive (+) terminal.

- Interruptions to the power supply may result in data loss. A memory saving device can be uses to maintain vehicle data.

- Prior to installing the battery, clean the battery compartment.

- Ensure that the battery is secured tightly.

- Clean terminals and battery clamps and lubricate slightly with acid-free, dilelectric grease.

- When fitting the battery, first connect the positive (+) terminal and then the negative (-) terminal. Ensure that the clips are secured.

- Some vehicle batteries are fitted with a hose and an elbow attachment for the discharge of the battery gases. Should this be the case in your vehicle, the hose is to be inserted into the corresponding degassing vent in the battery via the elbow. If a degassing vent exists on the other side, this must be closed with a sealing plug.

- Should you require a replacement sealing plug, or a degassing hose, please contact your local automotive specialist.

Maintenance

- In order to ensure long battery life, the following instructions should be followed:

- Keep the surfaces of the battery clean and dry.

- Check the acid levels regularly at “non maintenance free batteries” and if necessary top up with deionized or distilled water. Never top up with acid. If a substantial water loss occurs, an expert should check the voltage regulator inside the car.

- Do not put so-called “additives” into the battery acid.

- Warning! Should the open-circuit voltage fall to ≤12.5 V, recharge immediately in order to prevent lasting battery damage.

- AGM batteries are sealed and must not be opened. Acid density measurement and topping up with distilled water are neither possible nor necessary. Quarterly recharging of the battery greatly prolongs its life.

Jump Starting

- Due to the vehicle’s sensitive electronic components, starting assistance should generally be provided exclusively using a booster.

- Providing jump starts directly between vehicles can cause voltage spikes upon disconnection, potentially damaging or even destroying the vehicle’s electronic systems.

- Therefore, it is essential that the following procedure be strictly observed when using starter cables!

- Standardized starter cables (e.g. in accordance with DIN 72 553) should always be used for giving starting assistance.

- Read the jumper / booster cable manufacturer instructions.

- Only connect batteries with the same nominal voltage.

- When connecting the terminals, turn off both vehicle engines!

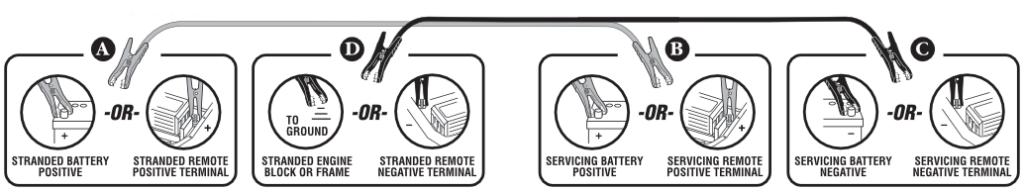

- First connect the two positive terminals (A) with (B). Then connect the negative terminal of the assisting vehicle (C) with (D), the blank metallic point on the vehicle needing assistance, away from the battery. (Observe the instructions of the vehicle manufacturer.)

- Now start the vehicle needing assistance for a maximum of 15 seconds. Do not start the assisting vehicle.

- When disconnecting the terminals, remove the cables in the reverse sequence to the below.

Storage

- Charge the battery (see Charging) and store in a cool dry place.

- Should the battery be left in the vehicle, disconnect the negative terminal.

- Regularly check the open-circuit voltage (see Maintenance).

Disposal

Proper Disposal of Lead-Acid Batteries

Proper disposal of lead-acid batteries is essential to protect the environment and public health. Follow these key steps to ensure responsible handling:

1. Never Dispose with Regular Trash

Lead-acid batteries contain hazardous materials like lead and sulfuric acid that can harm the environment if not properly managed.

2. Use Authorized Collection Centers

- Recycling Facilities: Locate local recycling centers or automotive stores that accept used batteries.

- Retailer Take-Back Programs: Many retailers offer free battery recycling services.

3. Prepare for Safe Transportation

- Protect Terminals: Cover the battery terminals with non-conductive material (e.g., tape) to prevent short-circuiting.

- Secure Packaging: Place the battery in a sturdy container to avoid leaks or spills during transit.

4. Recycling Benefits

- Resource Recovery: Lead and plastic components are recycled and reused, reducing the need for raw materials.

- Environmental Protection: Prevents soil and water contamination from hazardous substances.

5. Follow Local Regulations

Ensure compliance with local laws and guidelines regarding battery disposal to avoid fines and contribute to environmental conservation.

6. Safety Precautions

- Wear Protective Gear: Use gloves and eye protection when handling used batteries.

- Store Properly: Keep batteries in a cool, dry place away from flammable materials until disposal.

Conclusion

Proper disposal of lead-acid batteries involves using authorized recycling centers, preparing batteries safely for transport, and adhering to local regulations. By following these steps, you help protect the environment and promote sustainable resource use.

Temperatures

Impact of High Temperatures on SLI Batteries

Battery Replacement: In hot climates, consider replacing SLI batteries more frequently, as high temperatures can significantly shorten their lifespan.

Accelerated Chemical Reactions:

Increased Self-Discharge: High temperatures accelerate the chemical reactions inside the battery, leading to a higher rate of self-discharge. This reduces the overall charge available for starting the engine.

Electrolyte Evaporation:

Loss of Electrolyte: Excessive heat can cause the electrolyte solution (a mixture of sulfuric acid and water) to evaporate. This reduces the battery’s ability to conduct electricity and can lead to irreversible damage.

Plate Corrosion and Shedding:

Degradation of Internal Components: Elevated temperatures promote the corrosion of the battery plates and can cause active material to shed. This deteriorates the battery’s internal structure, diminishing its capacity and lifespan.

Increased Risk of Thermal Runaway:

Safety Hazards: In extreme cases, high temperatures can lead to thermal runaway, where the battery generates heat faster than it can be dissipated, potentially causing leaks or explosions.

Maintenance Tips for Hot Climates:

Ventilation: Ensure the battery compartment is well-ventilated to help dissipate heat and prevent excessive temperature buildup.

Regular Inspection: Frequently check the battery for signs of overheating, such as swelling, cracks, or electrolyte leakage.

If batteries are subjected to high temperatures for long periods, this promotes both increased water consumption and grid corrosion. A corroded grid is no longer able to conduct current, and therefore the battery fails. Resultant grid growth can also result in battery short circuits.

Impact of Cold Temperatures on SLI Batteries

Reduced Cranking Power:

Chemical Reaction Slows Down: In cold weather, the chemical reactions within the battery that produce electricity slow down. This results in a decrease in the battery’s ability to deliver the required cranking power to start the engine.

Increased Viscosity of Engine Oil: Cold temperatures cause engine oil to thicken, making the engine harder to turn over. Combined with reduced battery power, starting the vehicle becomes more challenging.

Decreased Capacity:

Lower Effective Capacity: The battery’s capacity to hold and deliver charge diminishes in low temperatures. For example, a battery that performs adequately at 25°C (77°F) may only operate at about 50% efficiency at -17°C (1°F).

Increased Demand:

Higher Power Requirements: Cold weather often means using more electrical components simultaneously, such as heaters, defrosters, and lights, which places additional strain on the battery.

Maintenance Tips for Cold Climates:

Regular Testing: Have the battery tested regularly to ensure it maintains adequate charge.

Battery Maintenance: Keep the battery clean and ensure terminals are free from corrosion to maintain optimal electrical contact.

Proper Charging: Use a battery charger or maintainer to keep the battery charged during extended periods of inactivity.